SERVICE INFORMATION

GENERAL INFORMATION

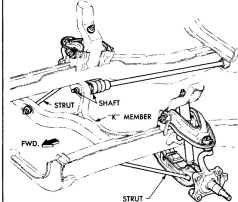

Construction of the fully unified body employs a bolted on engine and front suspension support member ("K" member), which is attached to the body horizontals (side rails) at four points. The lower control arm pivot shafts and struts are attached to the legs of the "K" members (Refer Fig. I).

62 x50 Fig. I-Front suspension mounting points

The torsion bar rear anchors are integral with the en gine rear support member in the body.

The torsion bar front anchors, which are part of the lower control arms, provide the means of adjustment or setting of vehicle front height.

The lower balljoints are integral with the steering arms. All balljoints and the torsion bars at the front of the rear anchors are effectively sealed against road splash by tightly fitted balloon type flexible seals. The suspension balljoints are of the semi-permanent lubricated type and should not under normal operating conditions require lubrication before 48 000 km or two years, which ever occurs first.

It is necessary to remove the plug provided in the ball joint to enable a grease fitting to be installed.

NOTE: When lubrication of suspension baUjoints is necessary, use only a hand type grease gun, filled with the specified lubricant (Refer Group 1). Use of pressure type grease equipment may damage the balloon type seals.

Remove the grease fitting after lubrication and re install the plug.

The balljoint and tie rod end seals should be inspected at regular intervals (Refer Group 1). Damaged seals must be replaced.

Caster and camber adjustments are made by cams on the upper control arm pivot bolts.

NOTE: Rubber bushings should not be lubricated at any time.

2-2-2

PROCEDURES

When replacement of a bushing is necessary, water may be used to aid in installation.

AU front suspension points that contain rubber should be tightened while the suspension is at the specified height (see specifications), with full weight of vehicle on its wheels.

Lower ball joints, steering arm assemblies, should not be replaced for looseness if the axial end play (up and down movement) is under 1,77 mm (.070").

Looseness of this nature is not detrimental and will not affect front wheel alignment or vehicle stability.

PREPARATION FOR CHECKING FRONT WHEEL ALIGNMENT

Front wheel alignment is the mechanics of adjusting all the inter-related factors affecting the running and steer ing of the front wheels. Incorrect alignment of front wheels will result in hard steering, abnormal tyre wear as well as braking problems.

The method of checking alignment will vary, depending on the type of equipment being used. The instructions furnished by the manufacturer should be followed in con junction with the specifications recommended by Chrysler Australia Limited.

NOTE: Do not attempt to modify any suspension or steering components by heating or bending.

All checks and adjustments should be made in the

following order.

(1) Front suspension height. (2) Caster and camber.

(3) Toe-in.

(4) Steering axis inclination. (5) Toe-out turns.

(6) Headlight aiming if height has been adjusted.

A check of steering axis inclination and toe-out on turns is valuable in determining if parts are bent or dam aged. Bent or damaged suspension and steering linkage parts must be replaced. When replacements of this kind are made it is important that other front end parts are checked and front wheels re-aligned.

Before any attempt is made to check or correct caster, camber and toe-in, the following preliminary checks and necessary corrections must be made on those parts which influence the steering of the vehicle.

(1) Inflate tyres to recommended pressure. All tyres should be the same size, in good condition and have equal wear. Note the type of wear to aid in diagnosing (Refer Group 22).

(2) Check suspension and steering linkage pivot points for excessive looseness, rear spring 'U' bolt nuts cor rectly tightened and the rear wheels aligned evenly with the front wheels. Check that the front suspension vehicle height is as specified with the vehicle standing on a level floor, or on an accurate wheel aligner.

The fuel tank should be full (or equivalent weight placed evenly in boot), but there should be no other load, either luggage or passengers, in the vehicle.