MASTER CYLINDER OPERATION

The tandem master cylinder unit separates the front and rear brake hydraulic systems. If one hydraulic system fails, the other, either front or rear will operate to retard the vehicle.

Normal Operation

When the brake pedal is depressed the primary piston moves forward compressing the primary return spring and simultaneously moving the secondary piston. This occurs because of the difference in spring tension between primary and secondary piston return springs (the former is stronger).

As the pistons and primary seals move past each com pensating port, fluid is displaced from the master cylinder outlets to the wheel cylinders and pressure in each of the hydraulic circuits increases. Under normal conditions the fluid pressure developed in the primary or front brake circuit (between the secondary and primary pistons) sup plies the force required to operate the secondary or rear brake circuit. The fluid pipes to the front and rear brakes are separated completely and both systems operate simul taneously and in a balanced manner to retard the vehicle.

Rear Brake (Secondary Circuit) Failure

As the brake pedal is depressed the primary piston forces the secondary piston forward until it bottoms in its bore (there is no pressure in the secondary circuit). Once the secondary piston has bottomed, pressure is developed in the primary circuit which operates the front brakes to retard the vehicle.

5-3-2

Front Brake (Primary Circuit) Failure

As the brake pedal is depressed the primary piston moves forward until it contacts the secondary piston

| (there is no pressure in the primary circuit.) | \., |

This provides mechanical actuation of the secondary piston which pressurises the secondary circuit and applies

the rear brakes to retard the vehicle.

MASTER CYLINDER OVERHAUL Disassembly

(1) Clean the outside of the master cylinder and re move reservoir cap. Discard any brake fluid that remains in the cylinder.

(2) Hold cylinder by mounting flange in a vice equipped with soft jaws.

(3) Depress and hold the primary piston 12 mm (0.5") down the bore and remove the stop bolt located in the primary reservoir.

(4) Remove the primary piston assembly from the master cylinder bore.

NOTE: Do not remove the screw of the primary piston return spring assembly. This assembly is factory set and should not be dis-assembled.

(5) Remove secondary piston from the master cylinder bore.

• IMPORTANT. THESE SEALS MUST BE ASSEMBLED IN THE DIRECTION AN~ POSITIONS SHOWN.

• PRIMARY SEALS

,

SECONDARY SPRING SECONDARY PISTON CIRCLIP RETAINER SHIM

• SECONDARY SEAL

PRIMARY PISTON

SPRING CARTRIDGE

(NOTE: ADJUSTING SCREW SETTING MUST NOT BE CHANGED)

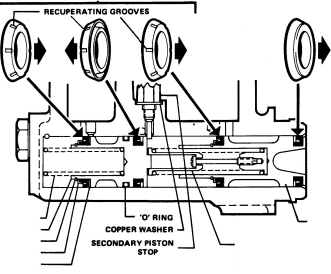

Fig. l-Cross sectional view of PBR Tandem brake master cylinder assembly